Every day, millions of cups of coffee are brewed around the world and just as many portions of coffee grounds are thrown away.

At OVPolymers, we don’t see coffee grounds as waste, but as a valuable raw material.

From this coffee waste, we create a unique sustainable plastic used to make our Re-Brew coffee cups sustainable cups that are literally made from coffee.

Coffee Grounds as a Raw Material

Our material consists of 30% coffee grounds and 70% recycled or biobased plastic.

By combining coffee waste with reused plastics, we create a strong, warm material with a natural look and feel.

Every cup has its own unique tone, depending on the origin of the coffee grounds.

We don’t just use coffee grounds as a filler; we use them as a core ingredient in the material itself. That makes each Re-Brew cup not just sustainable, but also genuinely connected to coffee.

Built to Last

All Re-Brew coffee cups are produced locally in Zwolle, The Netherlands.

They’re lightweight, durable, and made to withstand daily use.

Not a throwaway product, but a lasting, circular design for anyone who wants to make a more conscious choice.

With a lifespan of several years and a fully recyclable composition, Re-Brew cups are a sustainable alternative to traditional ceramics or disposable cups.

Fully Compliant with SUP Regulations

Our Re-Brew coffee cups are fully compliant with the European Single Use Plastics (SUP) Directive.

That means: no coatings, and no single-use waste.

Each cup can be completely recycled and turned back into raw material for new products at the end of its life cycle.

Take-Back and Closed-Loop Recycling

At OVPolymers, we go one step further.

We’ve developed a take-back model: once a Re-Brew cup reaches the end of its life, it can simply be sent back to us.

We process it again into new raw material for fresh Re-Brew cups.

This way, the material stays in circulation with no waste and no loss of quality.

A true closed-loop recycling system, where every cup literally becomes the foundation for the next.

Less CO₂, More Impact

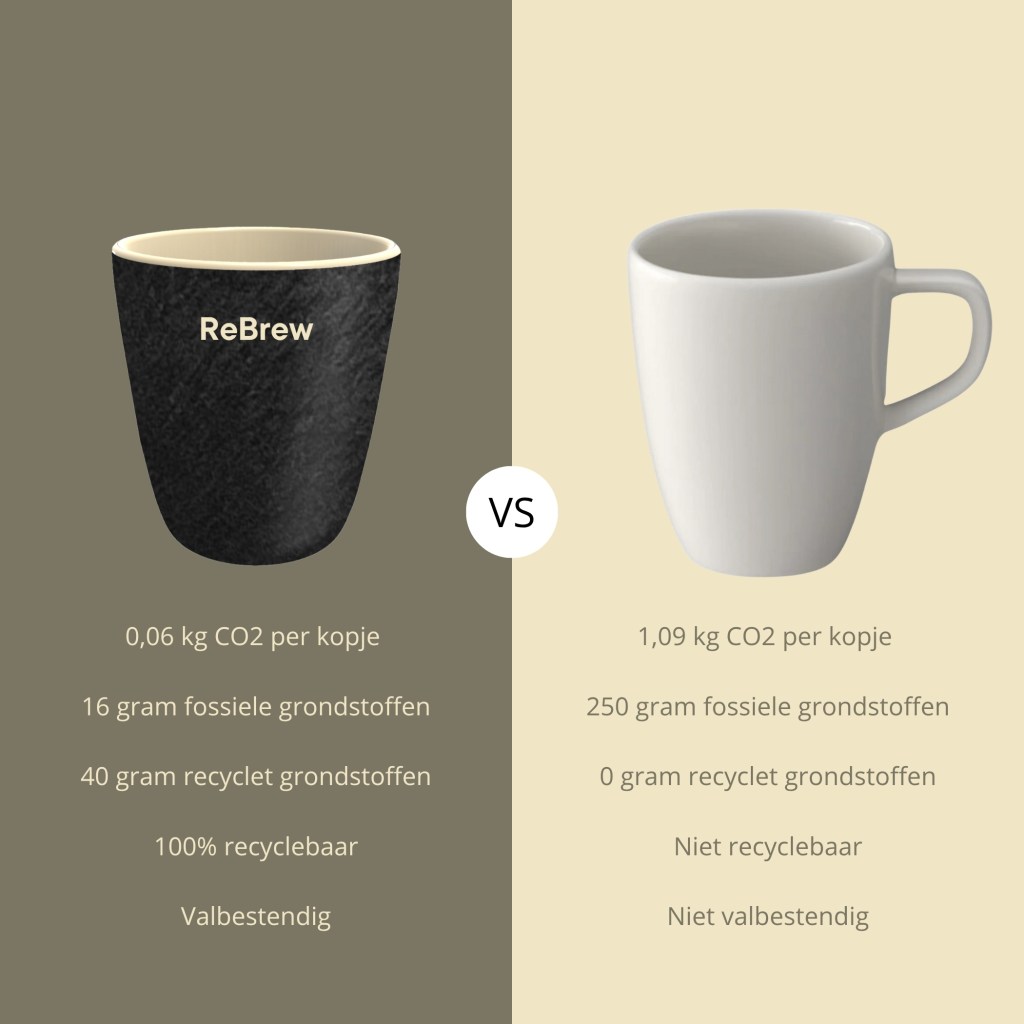

By using coffee waste and recycled plastics, we significantly reduce CO₂ emissions.

Compared to a ceramic cup, a Re-Brew cup saves 94% CO₂ during production.

That’s because ceramics require extremely high kiln temperatures (up to 1200°C), while our cups are produced at only 280°C.

Less energy, fewer raw materials, less carbon footprint.

Sustainability Without Compromise

At OVPolymers, we believe that circular products shouldn’t just be good for the planet they should also be beautiful, functional, and affordable.

That’s why we keep developing new applications for our Coffee Polymers from wall tiles to tableware.

Step by step, we’re building a world where coffee waste is no longer waste, but a source of new, sustainable materials.

Leave a comment